What is a gas storage?

A natural gas storage is a facility that can store natural gas for an indefinite period of time. Natural gas storages are typically located underground and are therefore called as well underground gas storages, or UGS.

The main function of gas storages is to inject and store natural gas at time of low prices and/or low demand and use the gas by withdrawing at times of higher prices and/or higher demand. We can identify three parameters to characterize a gas storage: working gas volume, injection capacity and withdrawal capacity.

Working gas volume

The working gas volume is the amount of gas that can be injected into the storage and withdrawn at a later moment in time during normal commercial operation. The working gas volume is smaller than the total volume of the storage. A part of the storage volume needs always be filled with gas. This so-called cushion gas is required to maintain sufficient pressure in the storage to allow for adequate withdrawal rates.

Injection and withdrawal capacity

The injection and withdrawal capacity define the maximum rate gas that one can respectively inject or withdraw from the storage. The injection and withdrawal capacity is typically dependent on the pressure level inside the storage. The pressure level depends on the amount of working gas injected, the inventory level.

The inventory level dependent injection and withdrawal parameters are also called ratchets. In case little working gas is injected into the storage, the pressure inside the storage is relatively low. As a result, the injection capacity is typically at its maximum value and the withdrawal capacity at its lowest value. The more working gas is injected into the storage, the higher the pressure. Consequently, the injection capacity decreases and the withdrawal capacity increases.

Storage cycling rate

The storage cycling rate is the number of times a storage can be fully filled and emptied during one year. The cycling rate indicates the main usage of the storage. It is defined by the ratio between injection/withdrawal capacities and the working gas volume. Storages with an injection/WGV ratio of over 100 days are called seasonal storages. These storage have a cycling rate close to 1 and can only be used for one full storage cycle per year.

Seasonal storages are typically used to inject gas during the summer and withdrawal during the winter. Thereby creating the required profile required to supply natural gas to residential customers. Storages with injection/WGV ration of less than 30 days are called fast-churn storages. Fast-churn storages have multiple full storage cycles during a year. These storages are typically used for short-term balancing of a portfolio and/or arbitrage short-term price differentials

Types of gas storages

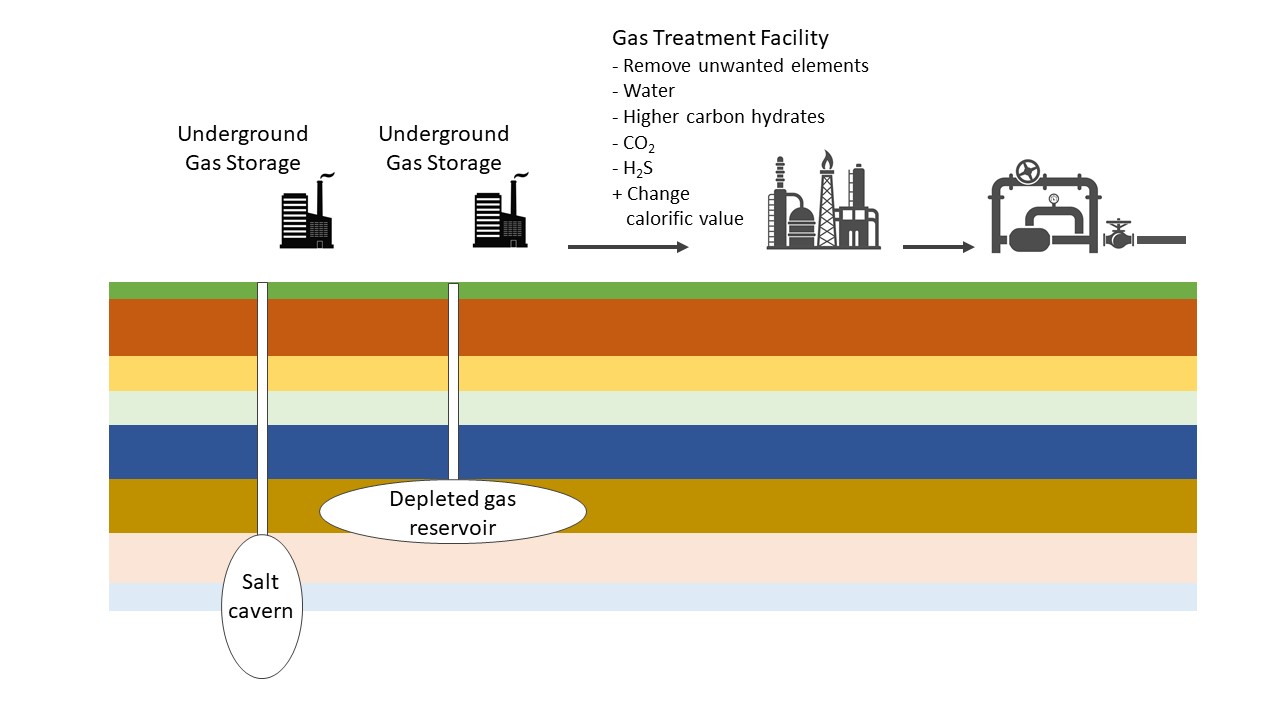

The most common types of gas storages are depleted gas reservoirs, salt caverns and aquifer reservoirs.

Depleted gas reservoirs are existing geological formations that have produced parts or all of the economically recoverable gas. The porous rock of many of these formations can be used again to inject, storage and withdrawal natural gas. Using depleted gas reservoirs can have advantages over other types of gas storage. Unproduced gas in the formations can be used as cushion gas, thereby lowering the investment costs. Furthermore, gas reservoirs are in many cases linked to existing gas infrastructure, again lowering investment costs. The cushion gas requirement of depleted gas reservoirs is in the order of 50% of the total storage volume. Gas storages located in depleted reservoirs have typically large working gas volumes, in the order of magnitude of hundreds of million cubic meters up to several billion cubic meters. Most storages in depleted fields are seasonal storages.

Salt caverns are man-made structures in thick layers of underground salt formations. The cavern are created by pumping fresh water down a borehole into the salt layer. The salt dissolves in the water and is pumped back to the surface. This process continues until the required size of the cavern is reached. Salt cavern storages require much less cushion gas than storages in depleted gas reservoirs, typically 25% of the total storage volume. Salt caverns are typically fast-churn storages.

Aquifers are natural, underground, porous formations that contain water reservoirs. The formation can be used to store natural gas. The process of converting a aquifer into a gas reservoir is typically long and expensive. The initial injection cycles need to be very slow to carefully push away the water. The amount of cushion gas required for an aquifer is high and can be up to 80% of the total gas volume. Aquifer gas storages are typically very large and used as seasonal storage.

Components of gas storage site

A natural gas storage site consists of the following main elements:

- Storage wells to inject and withdrawal the gas from the underground storage.

- Compressors to inject the gas into and withdrawal from the storage. During the injection compression is necessary in case the storage pressure is higher than the pipeline pressure, typically at high storage level. During withdrawal compression is necessary in case the storage level is lower than the pipeline pressure, typically at low storage level.

- Gas treatment facility. Gas that is withdrawn from the storage may not be at the required specification from the pipeline network. This step may include the removal of unwanted elements, water, higher carbon hydrates, CO2 and H2S. It may also be required to change the calorific value or Wobbe index of the gas before releasing the gas into the gas network.

KYOS Software models and Advisory

Natural gas portfolio management is about managing price and volume risks. KYOS helps to optimize a portfolio with natural gas storage and swing contracts. Trade in the markets to maximize the flexibility value and minimize risks!

For example, our flagship software model KyStore supports traders and portfolio managers in natural gas markets. The gas storage optimization software not only raises revenues from gas storage trading operations, but also provides accurate valuations and reduces risk with adequate hedge recommendations. The model uses advanced stochastics including Least Squares Monte Carlo techniques to capture the full optionality in gas storage facilities.

Please contact us for more information, just fill out the form in the black section below.